VFT-SSC Install

NOTE: Invictus Cockpit Systems makes no claim that our VFT will fit any stick base we did not make. It is up to the buyer to ensure fit before ordering. Review the datasheet.

PACKAGE CONTENTS

- Viper Force Transducer x1

- #4-40 Phillips pan head screws x2 (installed)

- 5-pin DIN connector (installed)

- X and Y axis cables

- #6-32 bolts x8

- #6-32 Locknuts x8

- TPU Deflection Gasket

- ASA Din connector Spacer

TOOLS REQUIRED

- Allen Keys

- Small flathead screwdriver

Step 1: VFT Connection

- Place your VFT upside down on a table with the PCB pointing up. Orient the VFT so that the two brass screw knobs on the blue square potentiometers on the PCB are pointing at you.

- Connect the 5 pin connector from the VFT to the 5 pin connector of the Thrustmaster Cougar HOTAS PCB.

- Connect the 3 pin connector wire labeled X Axis to the 3 pin connector on the VFT nearest you.

- Connect the 3 Pin connector wire labeled Y Axis to the 3 pin connector on the VFT farthest from you.

- Connect the X Axis wire to the X Axis connector on the Cougar HOTAS PCB. The X Axis connector is labeled, but just in case it is hard for you to see, it is on the same side as the 5 pin connector.

- Connect the Y Axis wire to the Y Axis connector on the Cougar HOTAS PCB.

Step 2: Manually Calibrate Your VFT

- Using the original Cougar PCB USB Cable, connect the device to your computer.

- Open the Cougar CCP on your desktop.

- Navigate to the start-up & calibration tab.

- Click the manual calibration button.

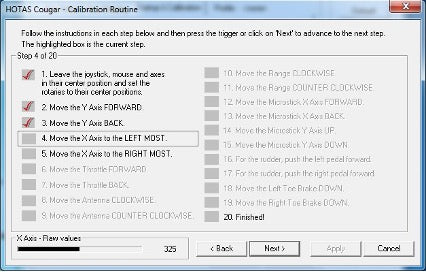

- Click next until the software directs you to move y-axis forward, and adjust the brass screw on the blue trim potentiometer on the VFT PCB using a small flathead screwdriver until you get a raw value of 324. You will not need to calibrate the Y axis back value as it will carry over.

- Click next until the software directs you to move the X-axis to the left most, then adjust the brass screw on the x-axis trim potentiometer until you get a raw value of 324. You will not need to calibrate it to the right as the value will carry over.

- Jump back to step 1 of the calibration menu.

- Now finish the calibration following the calibration steps of the HOTAS CCP menu.

- Once your VFT is calibrated to your environment, disconnect the wires from the Cougar PCB, feed them through your stick base, and then reconnect them.

- Install the eight mounting screws into your stick base. Recheck your calibration. (Review the VFT datasheet for hole mounting patterns to ensure your stick base will accept the VFT)

It is important to note that any changes to the environment may affect the calibration of the VFT. Changes in temperature, humidity, etc. can affect it. Additionally, the strain of screwing the VFT into a stick base will also throw off the calibration. For this reason, our stick bases have access holes to allow you to adjust the trim potentiometers while the VFT is in place. If you do not have them, you may need to adjust the torque on various mounting screws around your stick base to find the sweet spot.

Curves and Dead Zones

Depending on how and where you mount your VFT, you may need to adjust the sensitivity of the stick. The sensitivity can be controlled by the curve settings in the HOTAS CCP axis shaping tab. Adjusting the curve is a matter of personal taste.

You can also set the dead zones, and they will not affect the curves. We recommend a dead zone of 10 for the center of both the X and Y axis.

Mechanical Center Play

The Thrustmaster sticks are notorious for the mounting nut to back off during use, which creates mechanical play in the stick. Tightening the screw on the bottom of the stick may resolve some of the play, but it will eventually return. The TPU deflection gasket will eliminate most of this by holding the nut in place with friction.

This horseshoe part below is another option to prevent the nut from backing out, but is omitted from the newest version of the VFT as it is no longer necessary for most users. If you have issues with the large attachment nut backing off, let us know and we will send you a part to help secure it. (Or send you a file to print it yourself if you have the capability)